Aromatherapy

Special: detailed information about homedistillation.

(work in progress-15/3/13)

This are my second home distillation web pages,

after the first ones almost fifteen years ago, with my first glass distiller of 2 liter.

I have been adding more and more details recently to this pages. I

recently did a lot of research on internet and realized that many

people have a distorted understanding of (home) distilling. I even

found people on Youtube announcing to make essential oils and actually

were making an oil infusing of some herbs! Other made very complicated devices, more based on

old alchemy methods than modern distillation. Many other devices are

simply to tiny, distilling only 200 or 300 gr of herbs is really to discouraging, as you can harvest barely some drops of essential oils!

Plenty of other devices use the middle-ages methgod of direct

fire, sometimes the herbs are directly put into boiling water. Have a

look at my

distillation basics pages to understand how old this method is!

Gildemeister & Hoffmann proved already in

1905 in

Barrême after extensive studies and lavender distillation

research that "water distilling" (feu nu or direct fire" ) even with a

separation of the herbs from the water, that is without an independant

steam generator:

-

altered the quality of the lavendel oil (less ester content)

-lowered the yield of lavender (up to 10%!)

-often gives a bad fragrance result

(Die Atherische Öle, Gildemeister & Hoffmann, 1929, III, 644)

I gave a lot of practical workshops since we moved

from Belgium to France and realized that I had to improve the glass

distillation unit:

Here you can see my second model of 10 liter that had a disapointing

result: difficult to fill and remove the herbs, lower yield compared to

the former 2 liter small model,

hydrosol/late quality with low yield and not of the best quality!

The new model should be:

-big enough to have a good yield of oils (minimum 10 to 30 ml for common oils like lavender, peppermint...)

-easy to add and to remove the distilled herbs

-have the right dimensions to give a nice hydrosol/lat of the same quality as the professionnal units give:

I once tried to make a bigger glass unit, but it was too long and gave

bad results, so I deceided to have a larger instead of longer alembic.

If

you distill in pyrex glass: You need a still of preferably 10 liter

(approx 3 kg of fresh herbs, up to 7 kg of crushed seed like anise seed)

It's possible to use 2 liter volume distillers but you will have just a small quantity of essential oils.

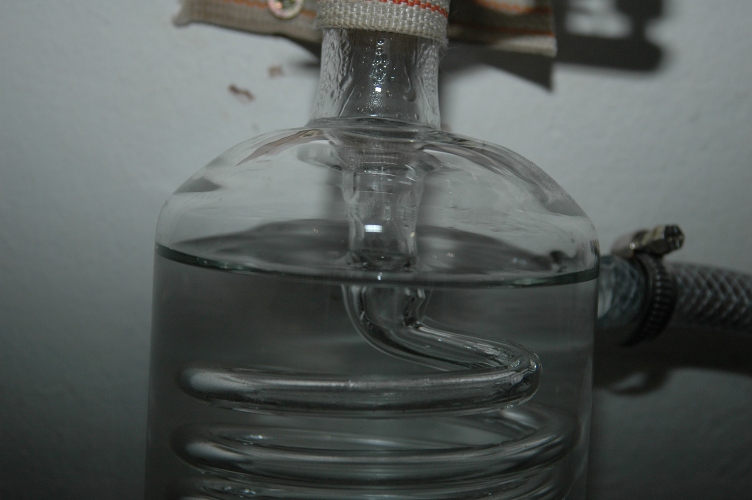

You will need a glass refrigerator

(cold water in, coming around the tubes coming from the still and

cooling down the steam+hydrolate/sol+essential oil), cold water is

redirected to another place (could be saved to be reused later)

Here

is the complete glass distillation still: you will need a steam

generator (here I use and old pressure pot of 10 liter, we fill with

2/3 of water, in order to have a good steam quality and enough for

distilling 3 kg of herbs during at least 1h30)

You

will need special laboratory tubes of silicone (hat resistent), in

order to connect the steam generator with the alembic. The teflon tab

is necessary to open from time to timer in order to let escape dirty

condens water (could give a bad smell to your harvest).

The alembic is connected with a glass connector towards the refrigerator (always keep it a bit lower).

Once distillation process started, the hydrolate/sol and the essential

oil come together in the florentin. The essential oil will float, the

hydrolate/sol will start leaving the florentin through the tiny tube,

into a bottle (always clean it first with steam or very hot water!)

Detail

of the

refrigerator

Detail : inserting the florentin under the refrigerator

Detail of the tap, necessary to remove from time to time condens water out of the still

In order to separate the essential oil and the hydrolate/sol you need first the florentin (two models on the right), later you'll need the condenser, in order to separate the final water left.

Details of the florentin

Final harvest of the essential oil, after decantation

Why glass and not a copper still?

The problem with copper is that it often interferes with the essential oils and can alter the color (red, green)

Glas is perfect... but fragile, that's why stainless steel is better, but only if it's food grade and polisched.

Is the form important?

Yes! I often see badly designed stills, even professional ones, giving a lot of troubles during the distillation process.

A very important detail:

in order to prevent condensation water to come back into the alembic,

(and so being distilled a second time gives a lot of bad reactions,

diminuisching the yield of the distillation

and gives bad fragrances to the essential oil and hydrosol/lat) you

need the tube coming from the alembic having a as large as

possible size, becoming smaller when reaching the refrigerator!

A good example:

Image on the left: The old Barrême distiller, on the right: a modern

"tête de Maure", a form starting large to end small, enabling a good

streaming of the steam. When the tube is too small a lot of the steam condenses and goes back to the alembic!

Regarding the form: a good example of a well designed still (copper) lavender distillation.

Here you have an good example of the form of the junction between the

alembic and the refrigeration system. Many other distillers have simply

a straight tube leading towards the refrigerator. Sometimes the lenght is much to long, or even the

direction: it should slowly go down, the natural way for the steam to

condensate into water and essential oil!

Other example: a Portugese copper distillation unit. It's nice to see but we have two major problems here :

-no separate steam generator ("feu nu "method

-the jonction between the alembic and the refrigerator is way to small: problems of condensating water.

Can the design of our glass distillation unit be improved?

Yes, it's difficult to make the same form

in glass as in the examples above. But this problem is ok for a five to ten

liter unit, using the same size of tubes for 20 or more liters would

cause big problems, easy to observe when you distill in glass:

condenswater coming back, appearance of a brown, water layer.

We found a way to be able to have a better control of the steam, adaptable for all kind of herbs, dry or fresh herbs:

Special decompression glass (with tap to evacuate

condens water), enable a better possibilty to have longer tubes from

the steam generator to the alembic. Enables a perfect controll over the steam quality. Without this device

you need a very short distance between the steam generator and the

alembic, to avoid condens water.

Michel

Vanhove Le Pompidou, 15/3/2013